How the World’s Whitest Paint Could Cool Down Planes (And Even Earth)

"Hearst Magazines and Yahoo may earn commission or revenue on some items through the links below."

The world’s whitest paint can reflect close to 98 percent of sunlight, cooling outdoor surfaces to 4.5 degrees Celsius below the ambient temperature.

Already the whitest paint in the world, this Purdue University creation is now 80 percent thinner.

Now, the research team is working on commercializing the paint.

The world’s whitest paint just slimmed down, making the sunlight-reflecting pigment light enough to adorn planes, cars, and trains.

Back in 2021, Xiulin Ruan, a mechanical engineering professor at Purdue University, developed the world’s whitest paint using nanoparticles of barium sulfate to reflect 98.1 percent of sunlight. That helped it cool outdoor surfaces by more than 4.5 degrees Celsius below the ambient temperature—cool enough to reduce the need for air conditioning.

🎨 Science explains the world around us. We’ll help you make sense of it all—join Pop Mech Pro.

But to make the paint practical beyond buildings, the world’s whitest paint needed an upgrade. Ruan tells Popular Mechanics he was able to get it “much thinner and lighter weight,” which he expects will make it the “preferred formula for thickness and weight-sensitive applications. These include cars, trucks, trains, airplanes, space vehicles, portable electronics, and wearables.”

The first iteration focused on the coolest white paint possible. “To achieve this level of radiative cooling below the ambient temperature, we had to apply a layer of paint at least 400 microns thick,” Ruan explains. “That’s fine if you’re painting a robust stationary structure, like the roof of a building. But in applications that have precise size and weight requirements, the paint needs to be thinner and lighter.”

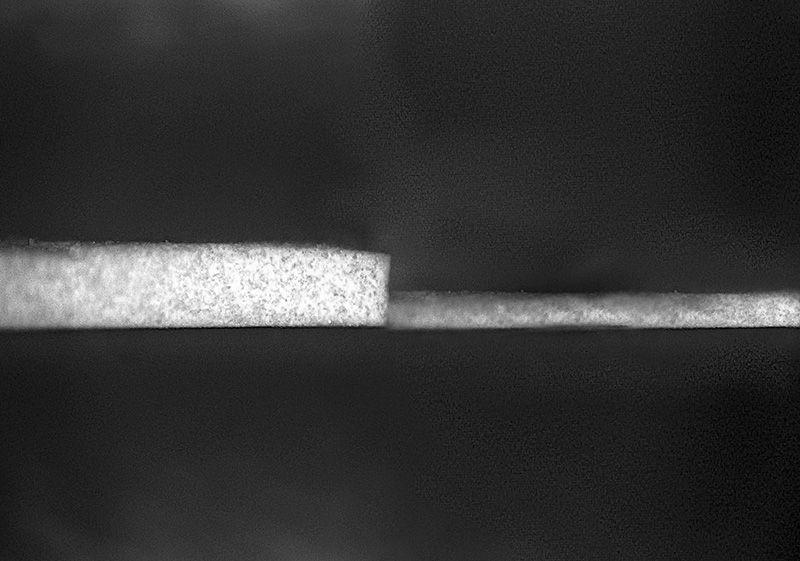

So, the Purdue team did what it does: research. The scientists experimented with additional materials to scatter sunlight, resulting in a nanoporous paint formulation incorporating hexagonal boron nitride, a substance mostly used in lubricants, as the pigment. The new paint achieves nearly the same benchmark of solar reflectance, albeit with a slight decrease to 97.9 percent of sunlight reflected. Still, the paint requires just a single 150-micron layer—substantially thinner.

“To reduce the thickness, we need materials with stronger scattering capabilities to the sunlight, which in turn require higher refractive index,” Ruan says. “However, materials with high refractive index often absorb the ultraviolet portion of the solar radiation, meaning [they] absorb more solar heat. This creates a dilemma.”

The team considered a mixture of materials, and Ruan says the hexagonal boron nitride turned out to offer a beneficial tradeoff where no UV light is absorbed, but the refractive index is still quite high. “Moreover,” he says, “an additional benefit we found about hBN is that its platelet shape also helps bounce back the sunlight.”

Through computer modeling, Ioanna Katsamba, a Ph.D. student working on the project, found that the “nanoplatelets are more effective in bouncing back the solar radiation than spherical nanoparticles used in previous cooling paints.”

By incorporating voids of air, making it porous on a nanoscale, the world’s whitest paint achieved a lower density; it weighs 80 percent less than the initial barium sulfate version. On Tuesday, the team published its updated research in the journal Cell Reports Physical Science.

“This light weight opens the doors to all kinds of applications,” George Chiu, a professor of mechanical engineering at Purdue, who was involved in the work, says in a news release. “Now this paint has the potential to cool the exteriors of airplanes, cars, or trains. An airplane sitting on the tarmac on a hot summer day won’t have to run its air conditioning as hard to cool the inside, saving large amounts of energy. Spacecraft also have to be as light as possible, and this paint can be a part of that.”

The concept of whitening paint to produce a reflective benefit has been around since the 1970s, and the Purdue project was the culmination of a six-year effort. Typical commercial white paints get warmer, not cooler, and even paints designed to reject heat only reflect between 80 and 90 percent of sunlight, and can’t make surfaces cooler than their surroundings.

“Using this paint will help cool surfaces and greatly reduce the need for air conditioning,” Ruan says. “This not only saves money, but it reduces energy usage, which in turn reduces greenhouse gas emissions. And unlike other cooling methods, this paint radiates all the heat into deep space, which also directly cools down our planet. It’s pretty amazing that a paint can do all that.”

Getting the new paint onto real-world applications, such as planes, is still a work in progress, but the Purdue researchers are on their way to making it a reality (and, importantly have filed for patents for the paint).

Ruan believes the initial formulation will make its way onto buildings, and the new, lighter version will likely first be seen in the automotive industry. “We have car and truck companies that are showing interest in it,” he says. “Airplanes and space vehicle applications are in harsher environments, and further developments are probably needed.”

As the paint continues its process toward commercialization, the upgrades won’t stop. The team is already looking to further minimize the use of volatile organic compounds, while testing and improving the long-term durability of the paints.

You Might Also Like

Yahoo Movies

Yahoo Movies