You Need a Torque Wrench in Your Toolbox

"Hearst Magazines and Yahoo may earn commission or revenue on some items through the links below."

If you’re like me, you’re probably snapped a few bolts throughout your DIY career. Tightening fasteners feels like second nature right up to the point where a tightened nut or bolt becomes worryingly loose. That’s why these days, I keep a torque wrench by my side whenever I tackle a job.

Torque wrenches are specialized ratchets that can be adjusted to apply a specified amount of torque to a nut or bolt. Professionals and DIYers alike use them to torque fasteners in an accurate fashion so as to apply a specific tightness to keep critical parts of a car from falling apart, failing, or being damaged. You’ll see them used most often by engine builders, as the tolerances and margin for error when building an internal combustion engine are extremely tight. If every bolt isn’t torqued perfectly, the engine can fail to generate compression or worse, damage itself on first startup.

To that end, it’s vital to use a torque wrench on nuts and bolts that are critical to your car’s continued function. We’re not saying use a torque wrench on everything, just the stuff that really, really matters, like engine components, suspension mounting points, and braking systems. Using an impact gun to tighten your lugnuts might sound fun and easy, but you’ll be regretting it after your wheels falls off on the highway.

I’ve been using a torque wrench a lot lately, actually, since I’ve been doing so much suspension work on my BMW M3 project. Leaving a bolt under-tightened on a control arm or upright could mean disastrous results, so having a torque wrench by my side is the only way I was going to get anything done. I’ve also used torque wrenches to tighten engine accessory bolts, oil pan bolts, and a handful of other miscellaneous things.

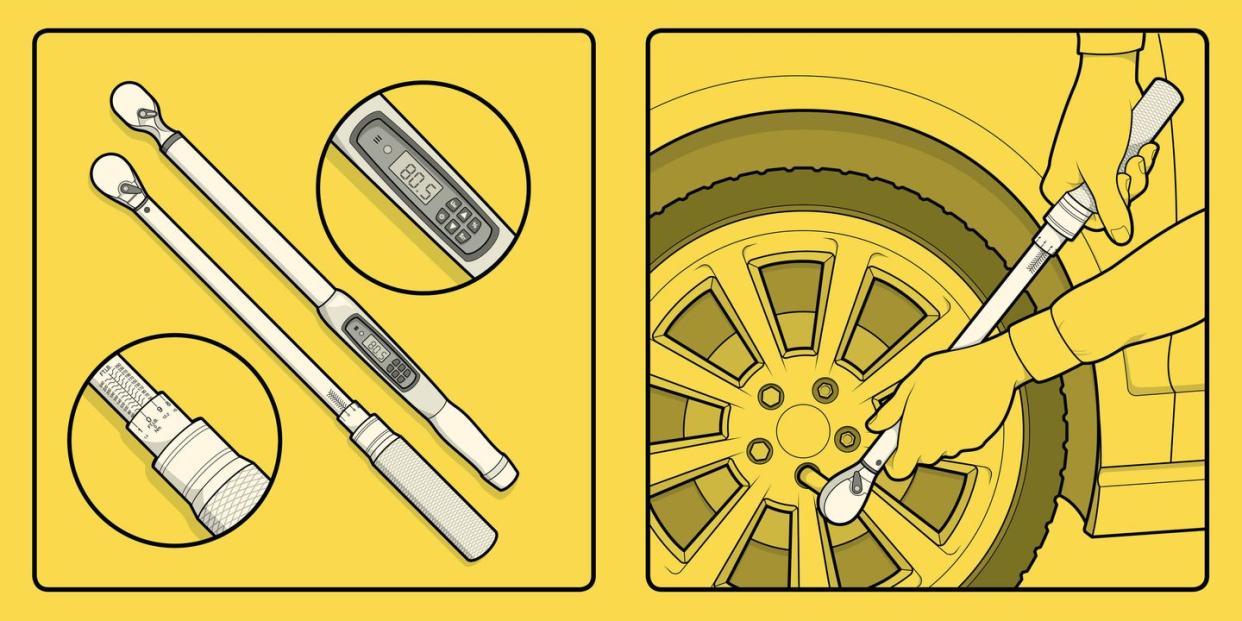

Torque wrenches are relatively complex tools, which means they’re on the expensive side. The best 1/2-inch Snap-On torque wrench, with its digital screen and on-handle LED lights, will cost you north of $700. I use Gearwrench’s 120XP Micrometer torque wrench. While it doesn’t have any of the fancy electronics, it does have a wide 30-250 ft/lb range and a +/- 3-percent torque accuracy, which works fine for what I’m doing. It’s yours on Amazon for just over $200. Need something more accurate? Gearwrench’s electronic 1/2-inch torque wrench is just under $250, and has a +/- 2-percent accuracy range. Need a smaller 3/8-inch size? Gearwrench also makes those, both in analog and digital forms.

You Might Also Like

Yahoo Movies

Yahoo Movies